New Products

MTE Hydrocal 1011 Portable Dissolved Gas Analysis

Megger EVX100 - EV charger interface for the MFT-X1

Megger EVT100 Electric Vehicle Tester

users, providing a single unit that can perform multiple tests. This unique instrument in the market, comes

with more than 8 testing features and the reliability of Megger’s testers, bringing greater testing possibilities to the photovoltaic and electric vehicle industries allowing effective Continuity, Bonding and Insulation Resistance testing.

complete suite of insulation resistance and low resistance tests, which also incorporates temperature measurement and compensation, plus continuity.

729 Pro Automatic Pressure Calibrator

Portable automatic pressure calibrator simplifies pressure calibration to 1,000 psi

The Fluke 729 Automatic Pressure Calibrator has been designed specifically with process technicians in mind to simplify the pressure calibration process and provide faster, more accurate test results. Technicians know that calibrating pressure can be a time-consuming task, but the 729 makes it easier than ever with an internal electric pump that provides automatic pressure generation and regulation in an in an easy-to-use, rugged, portable package.

The ideal portable pressure calibrator, the 729 allows you to simply type in a target pressure, and the calibrator will automatically pump to the desired set-point. Then, internal fine adjustment control automatically stabilizes the pressure at the requested value.

The Fluke 729 can also automatically test multiple pressure test points and automatically document the results. Calibration is as easy as typing in the starting and ending pressure and the number of test points and tolerance level. The 729 does the rest.

Back by popular demand! Relaunch of Ti300+, Ti401Pro and TiX501 Thermal Imagers

Fluke 831 Laser Shaft Alignment tool

Precision laser alignment made easy

The rugged Fluke 831 has an intuitive guided user interface that enables quick and complete shaft alignment without advanced training or complicated programs. And while it’s easy to use, laser alignment with the Fluke 831 is powerful enough for the skilled technician. You can cover more of your machines with all the functionality needed on the plant floor, from thermal growth to user defined tolerances and more.

Reduce costs by avoiding downtime

Misalignment causes at least half of all damage to rotating machinery, studies show. Instead of fixing the problem, teams often just treat the symptoms of misalignment and replace bearings, couplings, and seals because they think alignment takes too long.

Contrary to expectations, laser alignment can be fast and easy. So, every machine that is repaired and overhauled should be aligned – not just a few. Teams that embrace laser alignment can save thousands of dollars per year by avoiding downtime and energy waste and reducing the number of bearings and seals they have to replace.

Fluke ST240+ RCD Socket Tester

The Fluke ST240+ RCD Socket Tester with beeper checks that each wire in the outlet is properly connected to the building’s electrical system. Via the bright LEDs and included chart on the front of the tester you can quickly and easily verify the wiring of an outlet. Able to identify several common wiring errors, including reversed live and neutral wires and an earth fault, the ST240+ will give you confidence on your next job.

- Simple operation – Plug into socket; with the bright, easy-to-see LEDs, verify correct wiring or identify common wiring problems in both standard and RCD outlets

- Know more, faster –with the handy chart, quickly identify one of six wiring conditions for the outlet

- RCD outlets–with an integrated RCD test, you can feel secure knowing that your RCD equipped outlets are functioning properly

Fluke 1770 Series Power Quality Analyzers

With the new Fluke 1770 Series Power Quality Analyzers, you’ll never miss a critical power quality event. It can measure transients up to 8 kV, harmonics up to 30 kHz, dips and swells, as well as the voltage, current, and power measurements that enable you to characterize your electrical system.

This solution offers:

- Automatic measurements

- Straightforward user interface and setup

- Best-in-class specification

- Simple reporting platform

- Power directly from the measurement circuit

Megger EVCC300 EV Charger Tester

For anyone involved in EV charger, from manufacturing, installation, maintenance and beyond, you could all use this simple checking tool, that offers enhanced features, more than anything else in the market today.

For quick check testing that reads CP (Control Pilot) codes and CP max current codes, this product also offers checks:

- Mode 2 and Mode 3, single / two phase EV chargers

- Level 1 and level 2 charges up to 120 V

- Type 1 and Type 2 EV charger connections

- Nuisance trip testing

- Four safety tests including protective earth check and touch voltage measurement

- Four EV charger operations tests

Fluke 1770 Series Three-Phase Power Quality Analyzers

Fluke 1770 Series Three-Phase Power Quality Analyzers eliminate the complexities of power quality logging, troubleshooting, and analysis. Engineered to be the faster, easier way to perform power quality studies, the 1770 Series offers automatic measurements, a straightforward user interface and setup, best-in-class specifications, and a simplified reporting platform. The instrument can also be powered directly from the measurement circuit, eliminating the need to find a power outlet or use a lengthy extension cord

Fluke 835 Laser Belt Alignment Tool

The Fluke 835 Laser Belt Alignment Tool is the ideal tool to precision-align belt-driven machines in your facility.

Get more from your belt-driven systems through proper machine alignment. Misalignment can take years off your machinery’s useful lifespan — and lead to time and money spent on unnecessary repairs and replacements, as well as costly unplanned downtime.

TenneT solve communication turbulence at Rotterdam The Hague Airport

When TenneT got a call from the Dutch Radiocommunication Agency to investigate an issue at one of its substations that was causing significant air traffic communication problems between pilots and air traffic control, an innovative new detection tool held the answer to a fast, safe, and effective response.

TenneT is a leading European electricity transmission system operator with its main activities in the Netherlands and Germany. With over 23,900 kilometres of high-voltage connections, TenneT ensures the secure supply of electricity to 42 million end-users.

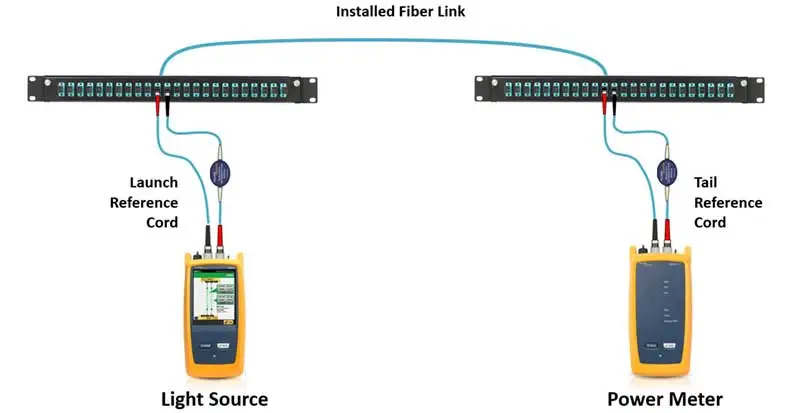

Insertion Loss

Insertion loss is the amount of energy that a signal loses as it travels along a cable link. It is a natural phenomenon that occurs for any type of transmission—whether it’s electricity or data. This reduction of signal, also called attenuation, is directly related to the length of a cable—the longer the cable, the greater the insertion loss. Insertion loss is also caused by any connection points along a cable link (i.e., connectors and splices).

Calibrating Humidity Sensors with a Mixed-Flow Humidity Generator Calibrator

We want to assume that when we take medication, fly in an airplane, eat food, use chemical products or perform other normal tasks that the products and processes we use are safe and work effectively. But it’s a dangerous world out there and that is why industries like pharmaceuticals, semiconductors, chemicals, aerospace, food processing and the like have regulations in place to ensure the quality of their products and processes. These regulations typically require regular measurements of many parameters including temperature and humidity. Making sure that measurements are accurate is where calibration comes in.

True RMS tools for energy efficient HVAC systems

The quest for energy savings drives innovations in highly efficient HVAC equipment. Much of the gains in efficiency have been made possible by variable speed motor drives and microprocessor controllers governing everything from blower fans and compressors to electronic expansion valves and thermostats. Although these electronic components help save energy, they present more complexity for HVAC techs.